We’re working with our partner DecTron USA to help them offer their products on the GSA MAS. As part of the GSA’s evaluation, candidate companies must provide the GSA with narratives of relevant past projects that they’ve worked on in order to demonstrate to the government that they have the chops to perform well on potential public projects. This is one of DecTron’s narratives.

In 2022, our partner DecTron USA landed a large contract with Evergreen Goodwill to overhaul all of its Northwest Washington Goodwill locations. The project’s objective was to equip these facilities with all new state-of-the-art ergonomic workstations, including specialized setups for photography, data entry, jewelry processing and book listing and shipping.

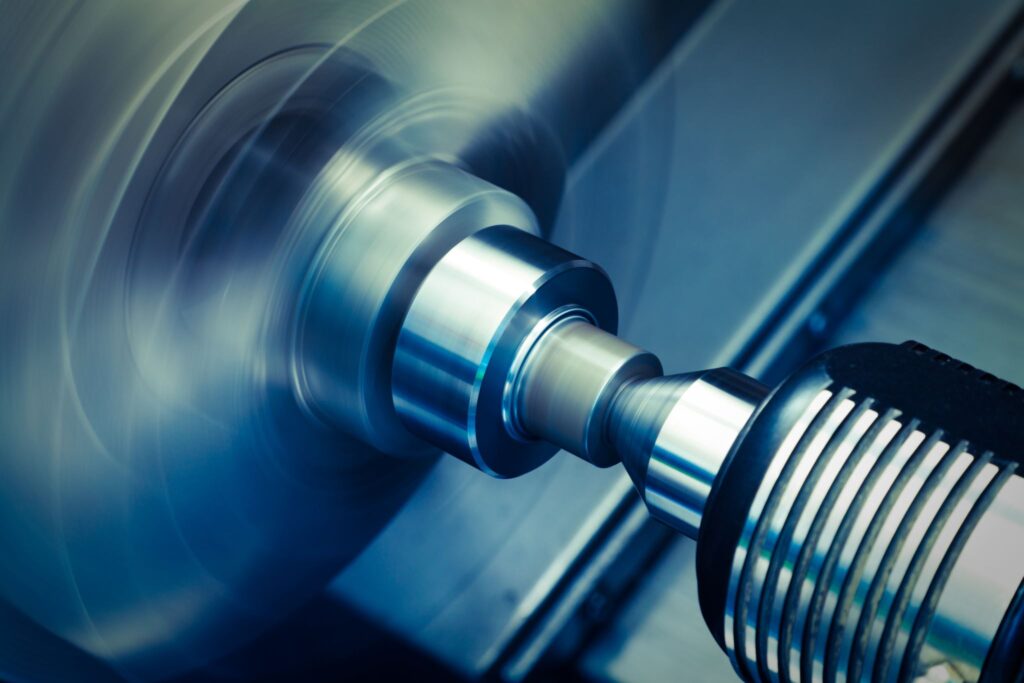

For this project, DecTron collaborated with a partner to design custom sit/stand workstations tailored to Evergreen Goodwill’s specific requirements. DecTron’s design and manufacturing teams worked closely with Evergreen Goodwill stakeholders, guiding the selection and creation of workstations specifically designed for various applications across different departments and job functions. As the project rolled out, DecTron sourced the raw materials sourced from Earle M Jorgenson and Coast Aluminum, raw materials suppliers with whom they have had a longstanding relationship. Utilizing in-house, industrial-grade equipment, including CNC machines, lathes and various finishing tools, DecTron assembled components that met their standards and the requirements of the project.

After initial fabrication, parts underwent the precision welding process, followed by quality inspections. Any imperfections were addressed through grinding, sanding, buffing and burnishing, preparing the components for powder coating or anodizing. Then came the final inspection, where subpar items were either scrapped or refinished, guaranteeing that only top-quality equipment reached the customer.

Per DecTron’s standard quality policies, they maintained thorough records of all quality and composition certifications from their metal distributors, verifying that all materials originated from U.S. mills. DecTron’s manufacturing and administrative processes follow strict compliance standards, including REACH, RoHS, and Proposition 65, which will apply to both domestic and international markets. Their quality control system allows for precise tracking of each manufacturing batch, easily enabling troubleshooting and continuous improvement should previously unknown issues eventually surface.

The Evergreen Goodwill project was a substantial undertaking, requiring production of 50 photography workstations, 50 computer workstations, 15 jewelry processing workstations, 16 book workstations, and 2 book shipping workstations. Each type of workstation was designed to accommodate different materials and functions, showcasing the company’s ability to create custom-built solutions for a diverse range of operational needs. DecTron’s project management team conducted materials cost analyses and developed the deliverables schedule facilitating project logistics for two major shipments to strategic locations in Seattle for subsequent distribution.

This project transformed the operational capabilities of Evergreen Goodwill locations and solidified DecTron’s position as a leader in custom workstation design and manufacturing. DecTron combined cutting-edge manufacturing techniques with a deep understanding of ergonomic design and workplace efficiency. Their execution of the Evergreen Goodwill project demonstrates their capacity to handle large-scale, complex assignments and their ability to meet customer requirements and, ultimately, customer satisfaction.